One of the last and largest structures for my layout is my Walthers

Cornerstone Northern Light & Power kit. I immediately fell in love with

this model due to its style and large, round-top windows. The building will

be installed in the vacant space between the track leading into the right

lower mountain tunnel portal and the road passing around the turn-table

area. Instead of a power plant, the Pioneer Press Daily Advertiser will be

the tenant. The model will be complete with custom lighting and a printing

press. I’ve always had an interest in press-printing and journalism and

because I already had the company name on a Woodland Scenics dry-transfer

sheet, I thought it was a good fit.

Like all Walthers Cornerstone kits, all pieces are precision molded with

quality materials. Besides the 4 walls, roof, one-piece chimney, and base

pieces, the kit includes an under-track hopper kit, roof support trusses, an

internal firewall, roof vents, and separate windows and doors. I always

prefer detached windows and doors as they make painting much easier and

convenient as there is much less masking required. I carefully cut each

piece off its plastic carrier structure and trimmed and sanded off any

spurs. I then washed each piece in warm, soapy water. This step is always

very important for proper paint adhesion.

I started by carefully assembling the 4 main walls, ensuring the structure

was kept level and the walls joined at a perfect 90 degrees. I painted the

main structure with brick red Humbrol enamel, thinned 3:1 with paint

thinner. I also used the same paint colour on the chimney and firewall

pieces. At the same time, I sprayed the windows and doors with Testors light

aircraft gray. I didn’t remove the windows at this point from their carrier,

making them much easier to paint in one easy step. Other small components

such as the roof vents and trusses were painted with metallic aluminum

paint.

After the main structure dried for 24 hours, I masked the entire building

to prepare for painting the trim and foundation. I used the same light

aircraft grey colour that I used on the windows for the trim, which took

about three coats as I was brush-painting them. Once the trim had completely

dried, I made any necessary touch-ups with either the brick red or light

aircraft grey paint using a fine detailing brush. I then weathered the

entire building with powdered pastels and sealed it with two coats of

Testors Dull-Coat.

I felt that the roof pieces lacked detail so I used trip styrene to make a

paneled look. I first divided each roof panel into four equal sections and

glued on 1mm x 1.5mm strip styrene. I then glued a piece of the strip

styrene along the total length of the edge of one roof section. I made sure

this piece overhung the roof panel slightly, thus covering the gap between

the two roof sections once they were assembled on the structure. The entire

roof was then spray painted flat black.

For the large double door, side entry door, and overhead bay door, I used

dark green enamel to add a bit more interest to the colour scheme of the

building. I masked off the door frames and transoms so they would remain the

light grey colour I had originally coloured them. The last step was to

weather the doors with dark powdered pastels and seal with a final coat of

dull-coat. The windows were also weathered and sealed with the same

method.

The window glazing included with the kit is thick and oddly obscure, so I

opted to use clear styrene from Evergreen. This product is thin and almost

perfectly clear so it looks a lot more like real glass. After removing each

window from its carrier, I carefully glued it to a clean sheet of the clear

Evergreen styrene. I glued each window side by side to get as much use out

of the styrene sheet as possible, leaving only a large enough gap between

each window to accommodate a razor blade. After the glue had dried, I

carefully cut each window with a sharp hobby blade and trimmed off any

overhanging styrene. This process was very quick and before I knew it, I had

a nice pile of glazed windows ready for installation.

Before installing the windows, I painted the interior walls with dark grey

enamel. I also scraped the paint off the surfaces of the windows and window

openings where glue would be applied for better adhesion. I then applied a

small bead of glue around each window and mounted it to the inside of each

opening, pressing down for several seconds to ensure it was properly seated.

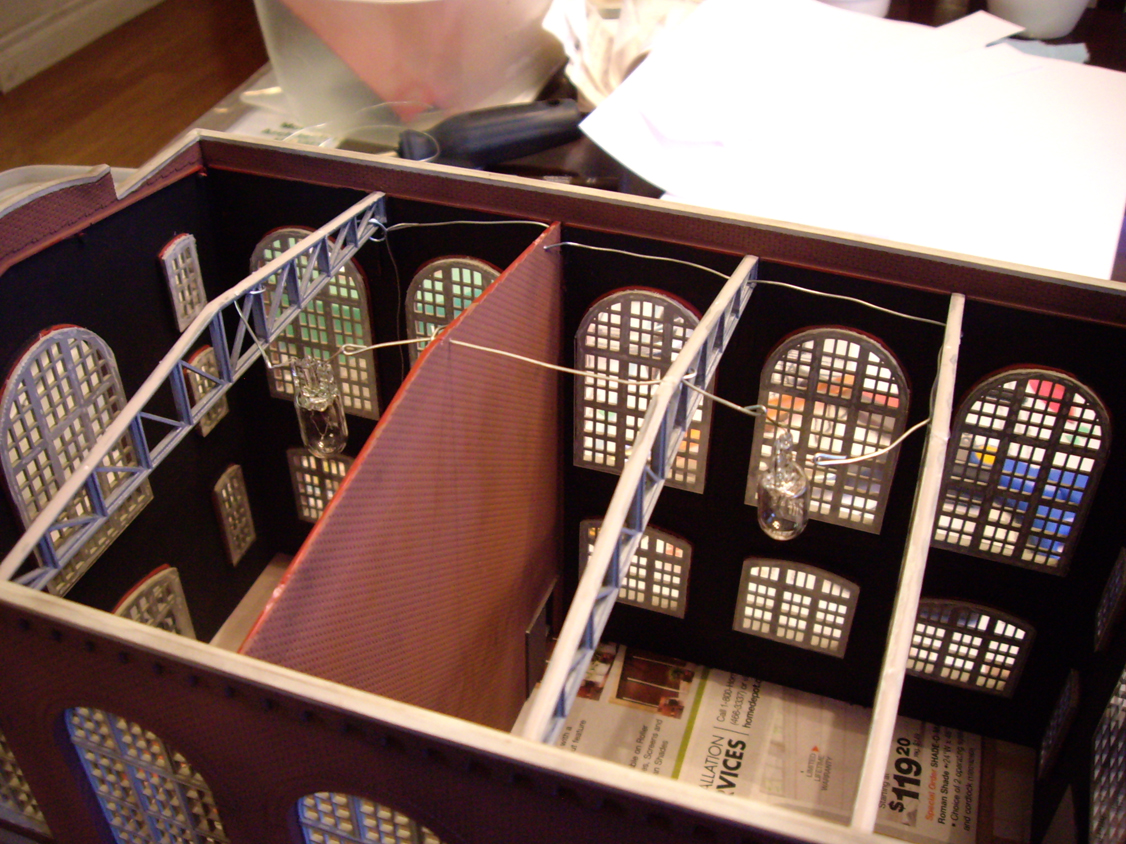

Once the windows were all installed, I added the three roof support trusses

and the interior wall. Though the interior wall could be optional, there is

no additional roof truss to replace it if it isn't used.

Lighting was next. I didn’t use the styrene light diffuser box method used

in previous models due to the fact that this building’s interior is

completely open and visible due to the large amount of windows. I instead

wired two automotive 12v bulbs between the roof support trusses using rigid

steel wire to support each bulb. I originally wired the bulbs in series but

changed to a parallel circuit as they were too dim. The wire leads run down

the back wall and exit out of two small holes in the foundation.

The interior was quite a lot of fun to build. A staple piece of equipment

for any press company is the printing press, so I immediately went to work

scratch building it scrap styrene. Once the press started to look somewhat

realistic, I sprayed it flat black and detailed it with metallic aluminum

rollers and highlights. The final and most imperative detail was the print

itself, which I created in Photoshop and printed as a long strip on standard

printer paper. I then glued 2 printed strips directly to the press, weaving

it in between the rollers.

The remainder of the interior is mostly just random pieces, shapes, and

parts thrown together in an attempt to make it industrial and factory-like.

The large box structure with the grate on top sits behind the interior wall

and serves to fill the large void. Its purpose is completely up to the

imagination! Just remember, the interior will be mostly out of view but

getting just a glimpse of any interior parts scene makes it entirely more

realistic and believable to the viewer.

Finishing the roof was the last step. I glued on the vents and added

weathering effects. My first attempt at weathering with powdered pastels

failed as they almost completely dissolved when I sprayed them with

dull-coat. I instead opted for dry-brushing the roof with steel and rust

enamel paint. Last, I placed the two roof panels to the main building. They

sit snugly on the roof trusses so there is no need to glue them. This allows

future access to the interior.

This kit was undeniably a lot of fun to build. It is currently the largest

structure I have ever put together. I might still be able to fit one or two

very small structures on my layout but definitely nothing as large as this

one. I must say that the feeling is almost bittersweet that this kit is

finished. Guess I will just need a larger layout.

4 comments

very nice !

ReplyDeleteLooks great!

ReplyDeleteCBSE – NCERT Developed the Chemistry Exemplar Books 2022 for 11th Class Students Purpose. Particular these Exemplar Books Prepare the Students and for Subject knowledge. so Students can Find the NCERT Chemistry Exemplar with Solutions 2022. NCERT 11th Chemistry Exemplar These Exemplar Problems help in Practical Exam and Final Exam. NCERT 11th Class Chemistry Exemplar Problems 2022 are the root Cause of Success, the more Exemplar Problems knowledge you will have. Considering this fact, NCERT aim to improve the Quality of Education Process in Collages has made an Attempt to Develop Resource Exemplar Problems from Class 11 in Different Subjects Biology.

ReplyDeleteFiberglass truss materials resist moisture and chemicals in harsh industrial environments.

ReplyDeletesquare truss rental orlando