My wiring and control panel are finally complete! My challenge this past week

was to move the control panel down to my basement and connect it to my

layout.

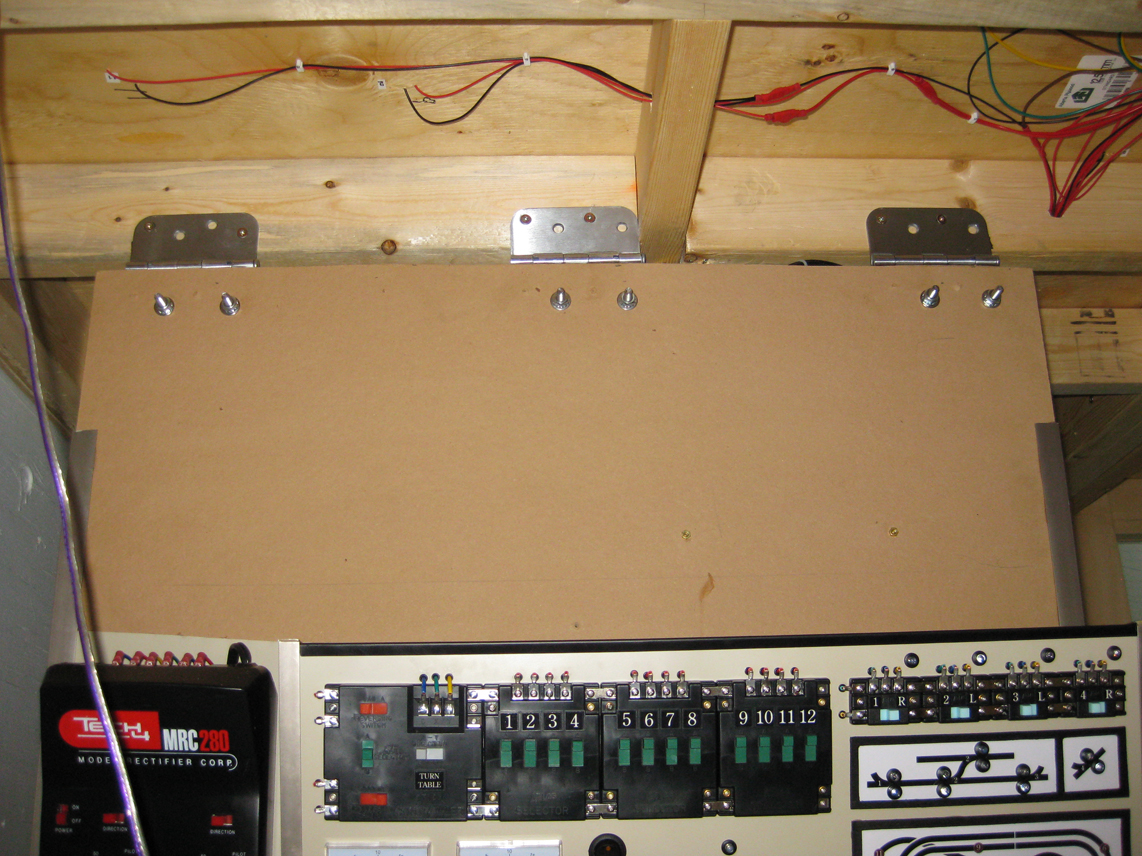

I first attached the back of control unit base to the three 4” hinges with six

1/4” bolts. This allows the control unit to fold under the table when not in

use. However, I have not yet made a final decision on how the unit will latch

when in its upright position. For now I fastened it in the upward position

with three screws.

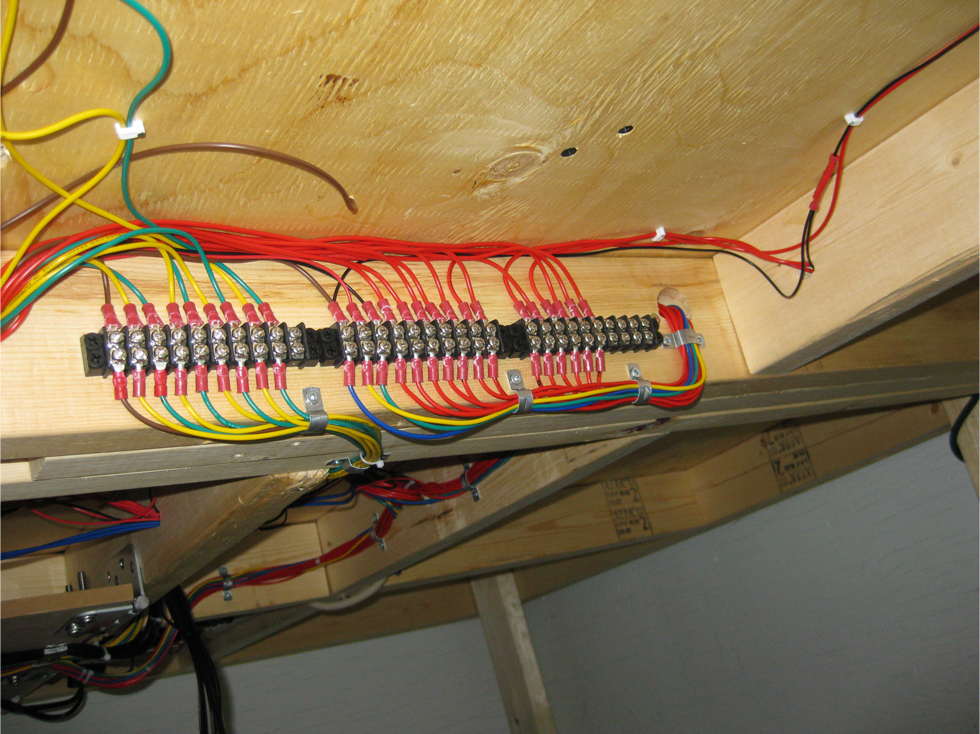

I ran the leads from the control unit and hooked them up to the corresponding

terminal screws on the previously installed terminal strips. The terminal

strips made it very easy to detect any crossed over wires, and even easier to

correct the problems as I only needed to swap the crossed wires to the correct

screws. Remember, it doesn’t matter how organized or well planned your wiring

layout is, mistakes will happen, so leave room to make corrections!

I kept the layout wires attached to the benchwork using small metal cable

fasteners. These can be purchased at any local hardware store. I purchased

mine at Canadian Tire for $1.99 for 20, which compared to other products and

retailers I found, is a pretty good deal. Small zip-ties also help to keep

wires organized and looking neat.

While testing my control unit, I realized that I needed a higher powered AC

power source to power my switch machines, separate from my MRC Tech 4 280

power pack. For this, I mounted an older MRC power pack to the underside of my

benchwork and ran the new AC line back into my control box. This second power

source can also act as an additional 12V DC source in the future. You can see

it in the top right corner of the image above.

To provide reliable safe power to the different components, I installed a

surge protected power bar below my benchwork. This is then connected by and

extension cord to a 120V wall outlet.

I originally didn’t plan a master on/off switch into my control panel design,

something I definitely should have done. Now I have no way to turn my

components off, including the power packs. To solve this, I purchased a rocker

switch ($2.99 from Princess Auto) rated at 120V 20A, which I tapped into the

cord on the power bar.

I then mounted the switch into a standard light switch cover panel. I drilled

a hole into the front of my benchwork beside my control unit so the rocker

switch panel could fit flush against the bench. This switch now cuts the power

off to the power bar so I can leave my layout plugged into the wall outlet at

all times.

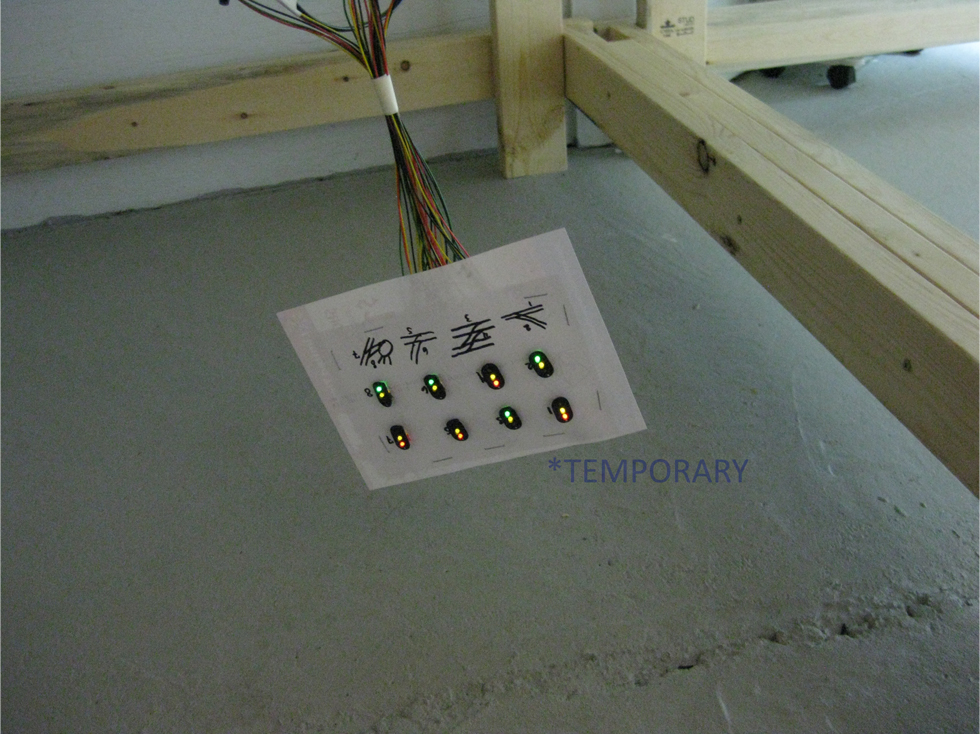

The track signals are still all displayed together on a temporary paper panel.

This is purely for testing and making sure the signals work correctly when

switching tracks. They will eventually be positioned on standards in the

necessary positions along the tracks.

Other than a few small required adjustments, everything works great as far as

the electrical system goes. The dual cab control works awesome and I couldn’t

be happier with how everything turned out. The next step will be to find a

method to easily raise and lower the control panel and latch it when it’s

upright. I’m also going to start smoothing out flaws in my track work and most

importantly, take out the steep grade coming off of my trestle.

Also check out my Design and Planning page for updated schematics for

different systems on my layout so far!

4 comments

Nice!!!!!

ReplyDeleteWow! You've cleared up a lot of questions I had about wiring! Thanks and well done!

ReplyDeleteWow! You've cleared up a lot of questions I had about wiring! Thanks and well done!

ReplyDeleteHP Board Plus Two Students this is 1st year your Education in Inter Colleges Session Start Month of Jun and July,HP Board Plus One HP Board +1 Textbook Every Year 3 to 4 Laks of Students Appear Collages,HP Board Plus One Students your Text Books Get Collages,Himachal Pradesh Board Plus Two Students Get your Collage Text Books Subject in Arts Group,Science Group,Commerce Group for Hindi,English,Urdu Medium Complete Text Books

ReplyDelete